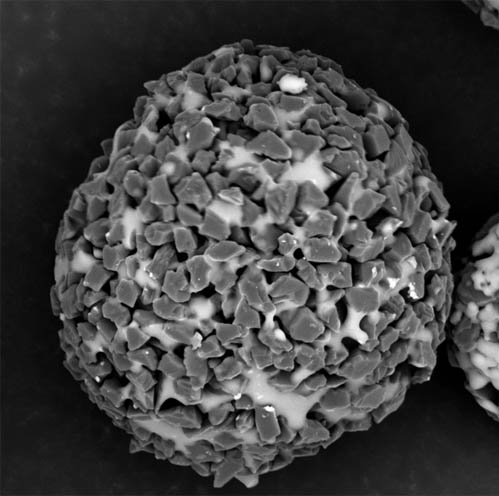

The "agglomeration" of diamond powder and grinding polishing fluid results in a very high rate of diamond powder agglomeration into spherical shapes, which forms a distinct advantage compared to traditional single crystal/polycrystalline diamond abrasives, minimizing processing costs for enterprises, with high speed, few scratches, and good roughness. At the same time, the size and particle size can be customized according to customer needs, and the production capacity has increased year-on-year, making it the best process choice for grinding materials at present.

1. Spherical appearance characteristics, with a multi blade structure at the micro level and a slightly natural mineral luster of agglomerated diamond abrasives;

2. Maintaining high grinding force during the grinding process can achieve surface quality that other diamond abrasives cannot achieve;

3. The spherical particles are mixed with diamond from inside to outside, and the powder continues to play a grinding role;

4. The agglomerated powder forms a spherical shape, and the product is isotropic, making it less prone to large scratches;

5. High usage rate, fast cutting speed, and good surface consistency of processed workpieces.

1. Compared with traditional single crystal/polycrystalline diamond abrasives, it has a distinct advantage: the rate of agglomeration into spherical shapes is extremely high, and the coarse/fine grinding effect is better.

2. It can minimize the processing time, consumables, and labor costs of the enterprise.

3. High speed, few scratches, and good roughness.

4. The size and particle size can be customized according to customer needs.

5. The year-on-year increase in production capacity is currently the best process choice for grinding materials.

Grinding fluid: used in conjunction with grinding skins to process hard and brittle materials such as sapphire wafers, silicon carbide wafers, and functional ceramics;

Grinding pad: used in conjunction with cutting fluid to process hard and brittle materials such as microcrystalline glass cover plates, sapphire wafers, and silicon carbide wafers;

Semiconductor wafer processing: mainly including sapphire substrates, silicon carbide substrates, sapphire window chips, silicon carbide chips, gallium nitride, etc;

Ceramic material processing: zirconia fingerprint recognition film, zirconia ceramic phone back case, and other functional ceramics;

Metal material processing: stainless steel, mold steel, titanium alloy, and other metal materials. As a leading China abrasives supplier, we offer a wide range of products for various applications, including grinding fluid, pads, and CBN powder for semiconductor wafer and ceramic material processing. Our CBN abrasive ensures efficient processing of metal materials like stainless steel and titanium alloy.